1980

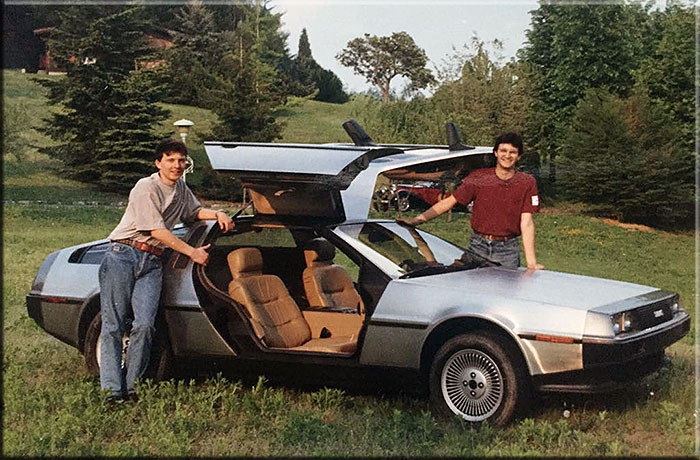

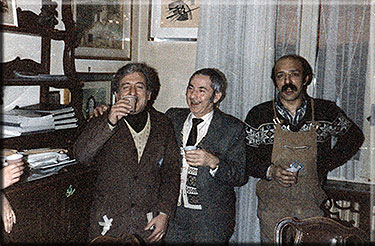

1987 Villarbasse, Alfredo Stola with Fabrizio Giugiaro and his DeLorean DMC-12.

1987 Villarbasse, Alfredo Stola with Fabrizio Giugiaro and his DeLorean DMC-12.

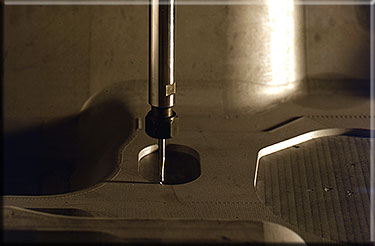

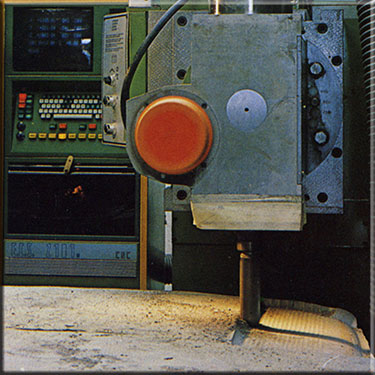

1979 testing a model with a motorized DEA with

1979 testing a model with a motorized DEA with

a special ruby-tip sensor.The 80s, as we will see later, would witness an extraordinary technological revolution.

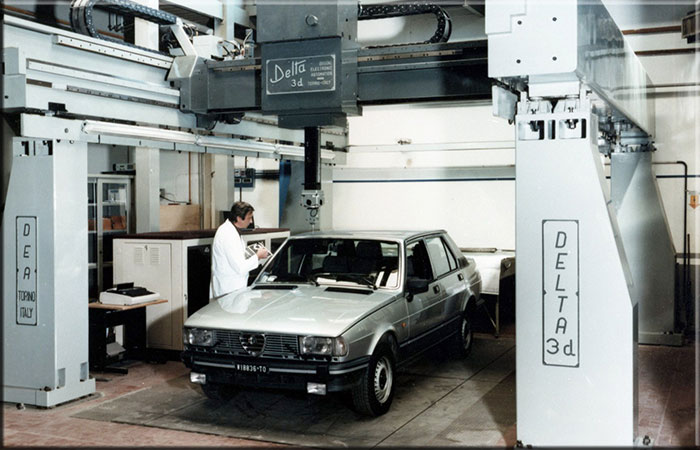

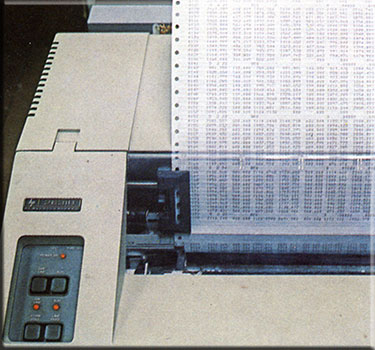

The difference compared to the past was that now the final models were examined with modern computer controlled Dea measuring machines from Turin.

The data collected was directly recorded using printers on special paper print outs.

This methodology, requested by Ford, was the prelude of self-certification testing.

1979 Stola Alfredo & Figli installs the DEA Delta 3d measuring machine with a working area of 5500 mm.

1979 Stola Alfredo & Figli installs the DEA Delta 3d measuring machine with a working area of 5500 mm.

Ferreo Versino, in the white coat, is the operator.

The model shop was well prepared, having just finished an expensive re-fit program of their Dea, updating all the machines originally installed in 1965.

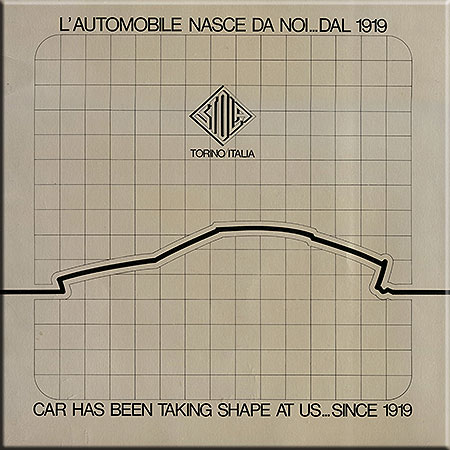

1981 The first brochure by Alfredo Stola & Figli showing customers the technological changes of the time.

1981 The first brochure by Alfredo Stola & Figli showing customers the technological changes of the time.

February 22 - March 2, 1981,

February 22 - March 2, 1981,

Milan Malpensa - New York - Detroit and back. Boing 747-200 Alitalia. February 22 - March 2, 1981,

February 22 - March 2, 1981,

Milan Malpensa - New York - Detroit and back. DC 10 North West.

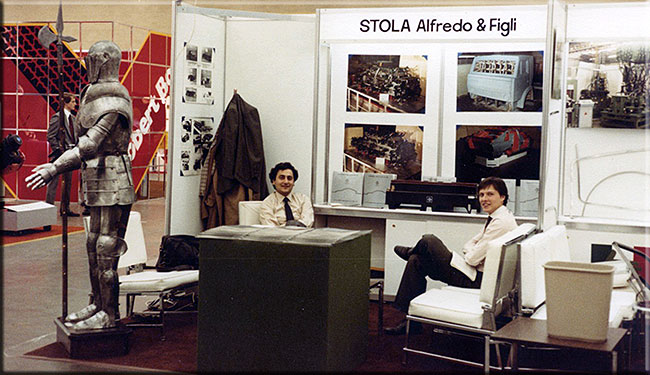

1981 Detroit,the Alfredo Stola & Figli stand,Cobo Hall exhibition center, on the left Guido Toninelli and on the right Alfredo Stola. In his American trip there is also the engineer Alberto Sasso.

1981 Detroit,the Alfredo Stola & Figli stand,Cobo Hall exhibition center, on the left Guido Toninelli and on the right Alfredo Stola. In his American trip there is also the engineer Alberto Sasso.

1981 Detroit Cobo Hall, Umberto Agnelli visiting the stand. On the right Alfredo Stola.Alfredo, in the side of his Uncle Roberto in the company, among the first assignments abroad in the winter of 1981 flies to Detroit together with a delegation from the Turin Chamber of Commerce.

1981 Detroit Cobo Hall, Umberto Agnelli visiting the stand. On the right Alfredo Stola.Alfredo, in the side of his Uncle Roberto in the company, among the first assignments abroad in the winter of 1981 flies to Detroit together with a delegation from the Turin Chamber of Commerce.

The goal was to set up and present a stand by Alfredo Stola & Sons at the car supplier show at Cobo Hall.

The American event was called SIAE, an international initiative aimed at showing to Ford of Europe the global vision of their own Italian "Partner Supplier".

The stand was unexpectedly honored also by the visit of Umberto Agnelli, one of the major shareholders of Fiat.

In the same exhibition building in Detroit at the motor show, 18 years later, Mercedes would exhibit the A Class Show Car, made in Turin by the family model shop.

March 1981. Commemorative medals were made for the occasion which were distributed from a medieval armor placed on the stand.

March 1981. Commemorative medals were made for the occasion which were distributed from a medieval armor placed on the stand.

March 1, 1981 Photographs by Guido Toninelli of a Sunday morning in Detriot down town. These images include the famous Renaissance Center, the old tram and the ancient skyscrapers from the 1930s and a car park adjacent to the Cobo Hall, which tells the story of four-year-old cars. In the photograph with the American flag you can see the Pontcharirain hotel where Stola, Sasso and Toninelli stayed.

March 1, 1981 Photographs by Guido Toninelli of a Sunday morning in Detriot down town. These images include the famous Renaissance Center, the old tram and the ancient skyscrapers from the 1930s and a car park adjacent to the Cobo Hall, which tells the story of four-year-old cars. In the photograph with the American flag you can see the Pontcharirain hotel where Stola, Sasso and Toninelli stayed.

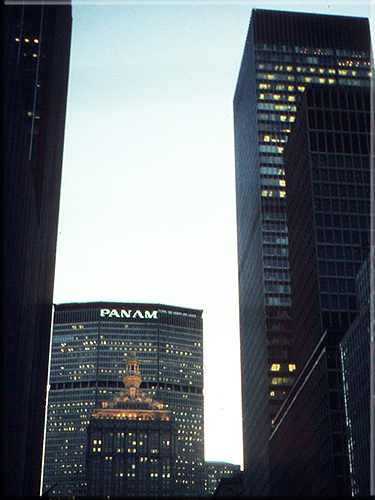

On March 2, on the return journey on the occasion of the long stopover at the Kennedy airport in New York, Alfredo Stola, Alberto Sasso and Guido Toninelli will decide for a quick visit to Manatthan.

March 2, 1981 New York. Alfredo Stola, Alberto Sasso and Guido Toninelli spend 4 hours in Manatthan.

March 2, 1981 New York. Alfredo Stola, Alberto Sasso and Guido Toninelli spend 4 hours in Manatthan.

March 2, 1981 New York Manatthan photos personally taken by Guido Toninelli.

In the summer of the same year, Alfredo and Massimo Stola were invited to work internships for two months.

Working as modeling apprentices, among the shirts and lunch boxes in the canteen at the Ford factory in Cologne-Niehl.

The opportunity given by the director Munch, was a way to integrate the technical relations between Ford and the modeling shop in Turin, satisfying the uncle's desire for his nephews to have practical experience from outside the company.

What is certain is that the experience in Cologne improved technical communication, as they had the opportunity to share their construction knowledge, also applying the basics of self-certification testing.

The internship, among other things, made it clear that in order to continue the cooperation with Ford, Alfredo Stola & sons, would have to adopt the primary hardware systems and "PDGS" software, used in all Ford plants around the world.

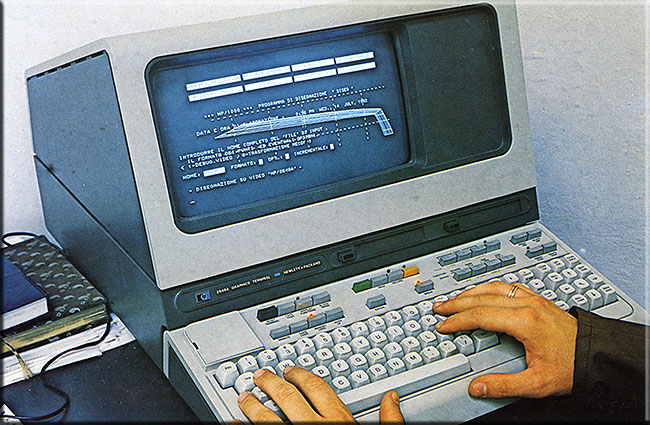

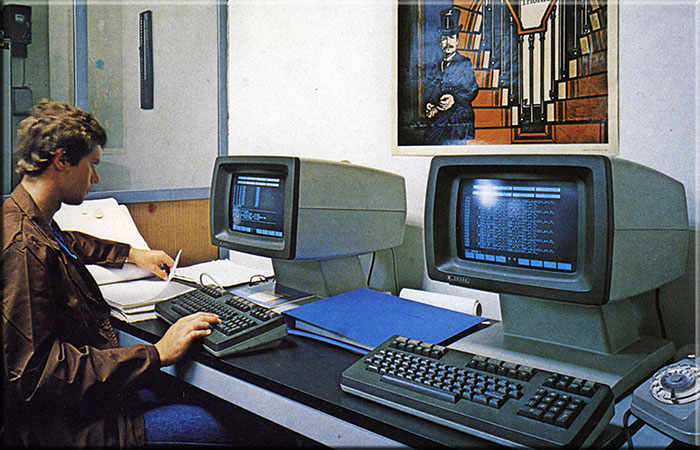

March 1981 Massimo Stola works on the keyboard of the first Helwet Packard 1000

March 1981 Massimo Stola works on the keyboard of the first Helwet Packard 1000

computer purchased by Alfredo Stola & Figli.

In 1980, a new technological innovation hit the world of automotive modelling.

The realization of numerical control models through automatic milling with special three-axis milling machines.

This was a real revolution in this environment, born, as many innovations were, in the United States of America.

The first to experience this new way of working in Italy are the two giants Fiat and Areitalia.

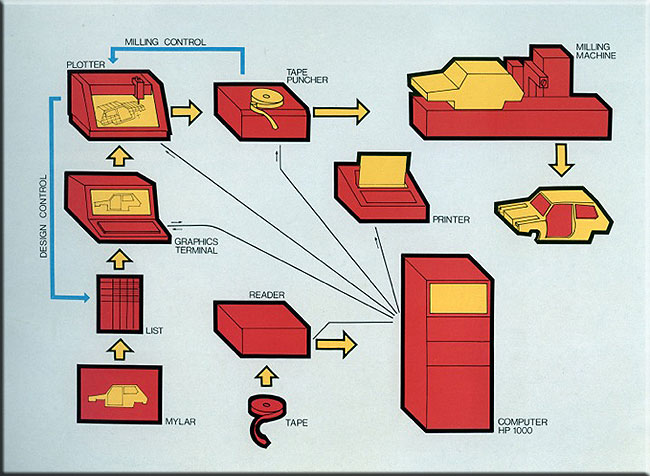

1981 The flow chart of activities, designed by Roberto and Massimo Stola to regulate

1981 The flow chart of activities, designed by Roberto and Massimo Stola to regulate

the numerical control model construction processes.

The acronym "Cad Cam" (Computer-Aided-Design and Computer Aided Modelling) was born and is still used in the same way, though it has evolved, increasing in performance year by year.

Roberto Stola, with finance and courage of thought, promoted this total change within the company, Alfredo Stola & sons was the third model shop in Italy, after Fiat and Pininfarina to adopt Cad Cam.

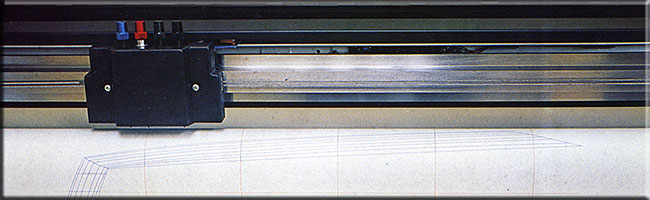

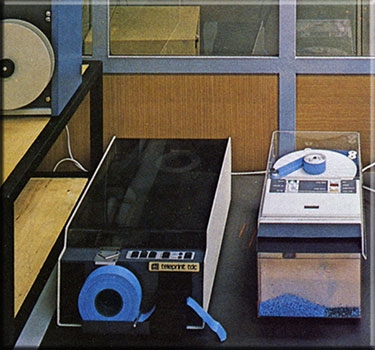

1981 The first plotter with different couloured nibs like Zeta.

1981 The first plotter with different couloured nibs like Zeta.

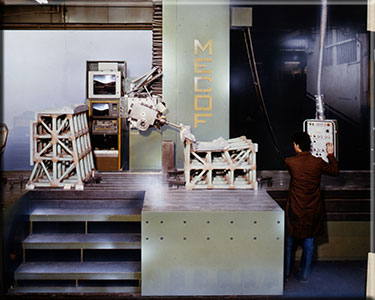

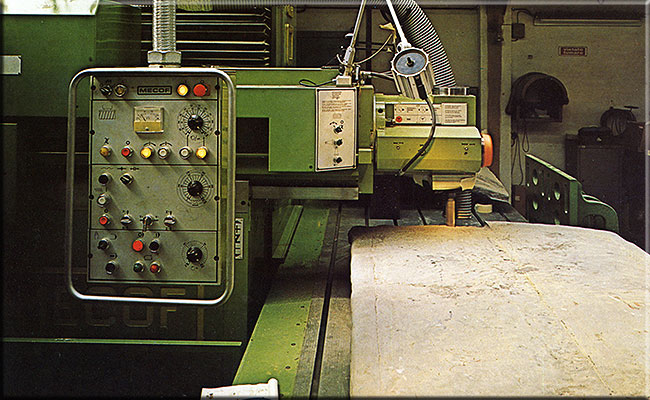

1981 the Mecof Cs 10 with numerical control is installed. Not knowing how to use numerical control, initially it is used as a normal cutter.The first major investments were in a Mecof type Cs 10 three-axis CNC milling machine with an 8-meter working area, managed by an ECS controller, two Helwet Packard 1000 computers and a 1500 mm Zeta roller plotter.

1981 the Mecof Cs 10 with numerical control is installed. Not knowing how to use numerical control, initially it is used as a normal cutter.The first major investments were in a Mecof type Cs 10 three-axis CNC milling machine with an 8-meter working area, managed by an ECS controller, two Helwet Packard 1000 computers and a 1500 mm Zeta roller plotter.

These were pioneering years, nights and Sundays were worked to realise the software programs, the translation of drawings with a ruler and the preparation of perforated ribbons of blue paper to transmit the data to the numerical control.

1981 Massimo Stola in the computer center department of Via Villa Giusti.

1981 Massimo Stola in the computer center department of Via Villa Giusti.

Massimo Stola

Massimo Stola

Massimo, son of Giuseppe Stola of the casting foundry ,was the young man who started this activity by joining the company in September 1980.

His work took great intelligence and sacrifice, computers were still tools for the few and the dedicated software could not be bought.

Massimo Stola compiled in person the programs, drawing on the works of the first students of three dimensional surface modelling, in particular the mathematicians Steven Anson Coons and Pierre Bézier.

1981 The paper tape punching machine for numerical control operation.

1981 The paper tape punching machine for numerical control operation. 1981 The Hewlett Packard printer.

1981 The Hewlett Packard printer.SIt was understood that the change would not only be technical but also human, in fact the fifty specialized modelers with an average age of 45/50 years were always used to build models with chisel and gouge, tracing and measuring them with guages.

The thought that a machine could automatically mill a model was a disconcerting development for their profession, above all the thought of being able to lose work forever took over.

The reality turned out to be not so severe, the modelers would still be needed to prepare the material for cutting and to finish the model by hand, removing the tool crests left by the milling and tracing out the detail lines. In 1981, Alfredo Stola & sons was marginally involved with Gallino of Rivalta Torinese, a plastic moulding company, to realize a master for testing for the front of the Lada Vaz Samara.

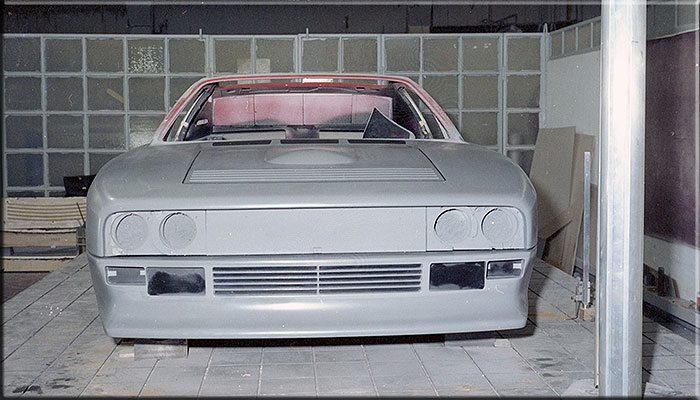

In 1981, Alfredo Stola & sons was marginally involved with Gallino of Rivalta Torinese, a plastic moulding company, to realize a master for testing for the front of the Lada Vaz Samara.

A project that was very innovative at the time, so much so that the Russian carmaker entrusted the complete design to Porsche Engineering.

The task of Gallino was to mould in plastic, a special front panel. The plastic material was not only for the bumper and front grille but also formed a ring panel positioned at the end of the bonnet and front fenders, linking them all together in a single part.

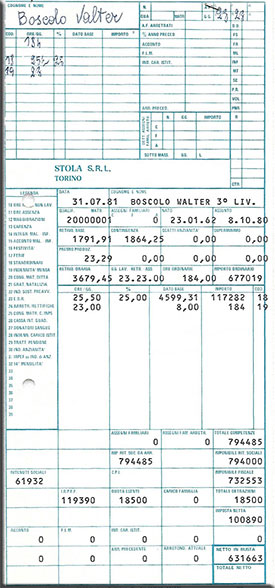

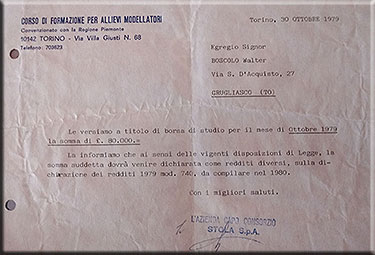

La Gallino asked Stola for their experience for the design of a super control device to measure the couplings of all the frontal parts, including the head lights. Given the contract with Porsche, Gallino was asked not to take pictures given the uniqueness of the solution for that time. The first paycheck of the student who became a modeler in 1980 Walter Boscolo.It was a time of distrust, but Roberto Stola managed to convince his workers that nothing bad would happen to them, indeed he promised that new opportunities and other types of specializations would be born of this modern technology.

The first paycheck of the student who became a modeler in 1980 Walter Boscolo.It was a time of distrust, but Roberto Stola managed to convince his workers that nothing bad would happen to them, indeed he promised that new opportunities and other types of specializations would be born of this modern technology.

In the meantime, as a consequence of these changes, there was an urgent need for a new profession; the surface modeller.

The need for the "new modeller" to perform manual surveys from complex technical drawings, and to insert the mathematical coordinates into the computer.

Once the data was processed, instructions were sent to the mills numerical control through via tool paths.

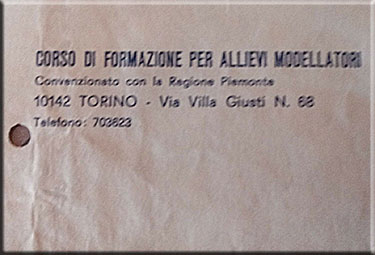

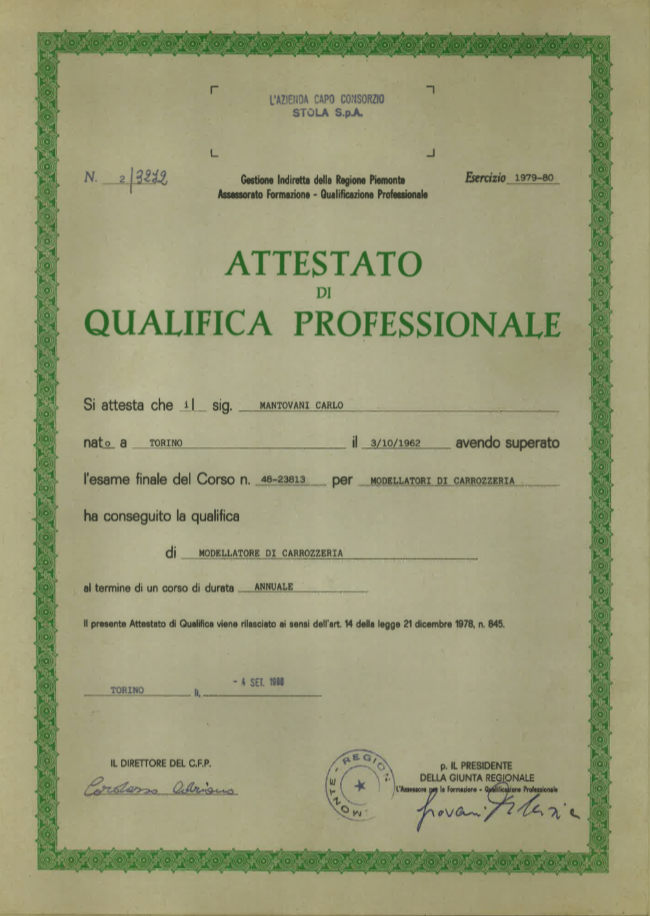

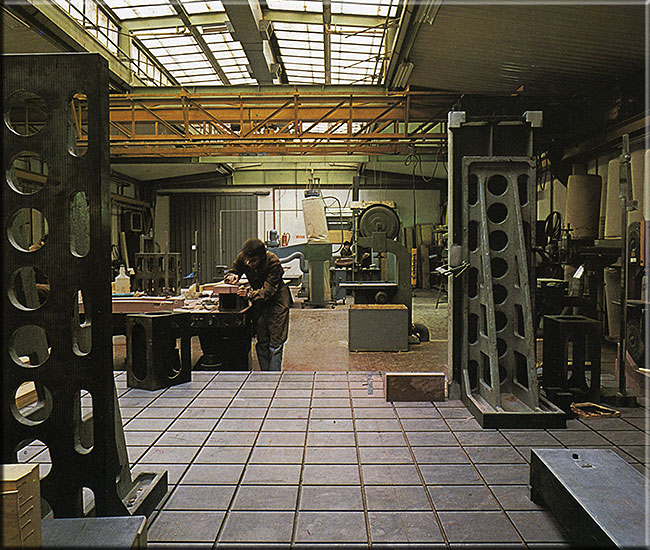

Three professional courses were established in 1980, 1981 and 1982, subsidised by the Piedmont region, with the participation of a selection of students from the professional technical schools of Torino Arti e Mestieri, San Carlo, and Giovanni Plana.

The three annual courses were held in the second entrance of Via Villa Giusti 68. In all 45 students were trained.

1979 headed paper of the modeling course of the

1979 headed paper of the modeling course of theAlfredo Stola & Sons.

1979 communication for tax compliance for the student Walter Boscolo.

1979 communication for tax compliance for the student Walter Boscolo. The Professional Qualification certificate from the modeling course of the student Carlo Mantovani.

The Professional Qualification certificate from the modeling course of the student Carlo Mantovani. 1981 In via Villa Giusti the already operational department from the first modeling course.

1981 In via Villa Giusti the already operational department from the first modeling course.

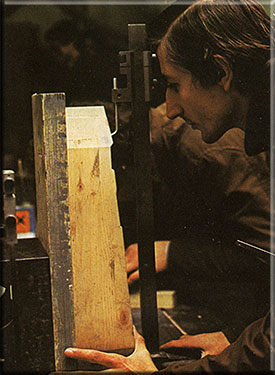

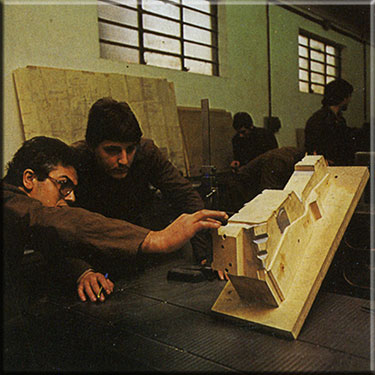

1981 Maccarini draws a model in

1981 Maccarini draws a model in

pine wood. Michele Adamo, one of the professors, checks the model just made by Tornatore Aniello.

Michele Adamo, one of the professors, checks the model just made by Tornatore Aniello.

Turin February 1982,via Villa Giusti 68, the students of the 1981/1982 course Bennici Salvatore, Rolando Maurizio, Ferrero Roberto, Spadone Saverio, Dinunno Giuseppe, Peiretti Aldo, Stola Alfredo, Mamusi Giuseppe, Leale Valentino, Rossi Adriano, Gualtiero Gianni, Carmignato Enrico.

Turin February 1982,via Villa Giusti 68, the students of the 1981/1982 course Bennici Salvatore, Rolando Maurizio, Ferrero Roberto, Spadone Saverio, Dinunno Giuseppe, Peiretti Aldo, Stola Alfredo, Mamusi Giuseppe, Leale Valentino, Rossi Adriano, Gualtiero Gianni, Carmignato Enrico.

Carlo Mantovani and Vincenzo Madonna, father of this group, are absent because they are

engaged in military service.

The professors were some of the best modellers, those who had worked with the founder Alfredo Stola who was then close to retirement.

Francesco Nada and Aldo Peiretti, coordinated by the young Michele Adamo, chief tester for Dea.

This decision to involve them as teachers convinced all the other modelers that the road mapped out by Roberto Stola was right for both themselves and for the company.

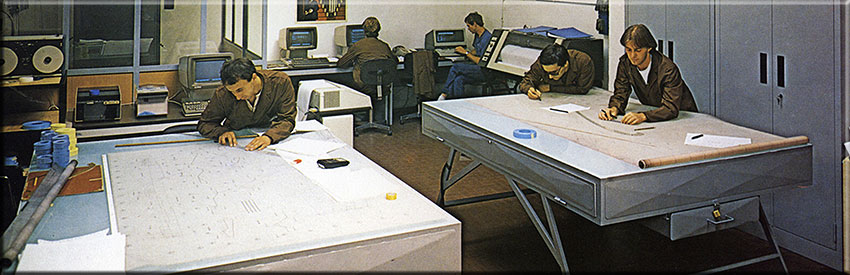

Even today in 2019 almost all of these former fifty-year-old students work in respected positions in Stola spa or in other concerns both in Italy and around world. Gradually, having learned to build models by hand, from the end of 1981 these youngsters were transferred from the workshop to the new department called "Calculation Center".

The work overalls were still brown, the chisels replaced by a keyboard connected to a computer, and the workshop was replaced with an open space office.

March 1982 Boys trained on the second professional modeling course. From the left we can see Carmignato,

March 1982 Boys trained on the second professional modeling course. From the left we can see Carmignato,

Ferrero Massimo Stola, Bennici and Rossi.

1982/83 Turin Alfredo Stola & Figli realizes the Master Models of the Fiat Duna sedan and sw.

1982/83 Turin Alfredo Stola & Figli realizes the Master Models of the Fiat Duna sedan and sw. The original photos of the master models were not found.

The original photos of the master models were not found.

Ford Europe was still a protagonist in this change, entrusting to the Stola company the milling of the first model built with numerical control.

In January 1982 ,the upper body stucture of the successfull Transit series was created.

March 1982 Massimo Stola with the Mecof CS10 milling machine performs the very first numerical control

March 1982 Massimo Stola with the Mecof CS10 milling machine performs the very first numerical control

milling test on two different Ford Transit upper bodies.

Practically an experiment, from manual input of the measurements from mylard drawings, to numerical control milling through computer processing.

This work was totally performed by Massimo Stola, including operating the Mecof CS 10 milling machine personally.

It was very special day and a significant change, seeing a model born without the use of the chisels guided by the hands, marked the beginning of a new era.

The milling of the models would take place gradually, continuing according to the situation and how convenient it was compared with the traditional manual technique.

Obviously exterior models are the first to be milled with numerical control, only later in 1986 the frame of the Fiat Tipo body side was the first internal structure to be milled with numerical control.

March 1982, the details of the very first numerical control milling of the Ford Transit upper body.

March 1982, the details of the very first numerical control milling of the Ford Transit upper body. March 1982, the details of the very first numerical control milling of the Ford Transit upper body.

March 1982, the details of the very first numerical control milling of the Ford Transit upper body.

March 1982 ,the milling of the Ford Transit upper body.

March 1982 ,the milling of the Ford Transit upper body.

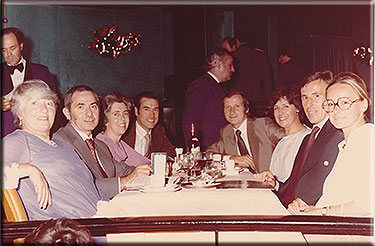

1979 Talk of the Town,London. Dinner with Ford managers. From left: Jane Kallar, Sid Kallar, Don Bidwell and wife, Alberto Sasso and wife.Despite the initiative of giving the support jig for free for the Cargo-type master of 1978, Ford, for logistical and process control issues, preferred to do the future assembly of the complete Master Models within its own plants in Germany and in Great Britain.

1979 Talk of the Town,London. Dinner with Ford managers. From left: Jane Kallar, Sid Kallar, Don Bidwell and wife, Alberto Sasso and wife.Despite the initiative of giving the support jig for free for the Cargo-type master of 1978, Ford, for logistical and process control issues, preferred to do the future assembly of the complete Master Models within its own plants in Germany and in Great Britain.

Nevertheless, in these years hundreds and hundreds of single models were milled in Turin both for exteriors and interiors.

Escort, Sierra, Fiesta, Orion, Scorpio, Transit, and Mondeo projects included, becoming an exclusive model supplier for Ford of Europe.

For reasons of industrial confidentiality, Ford imposed on the modeling firm an absolute prohibition in the taking of photographs, even for the company archive. It is unfortunately for this reason that there are no photographs of the work carried out in those years with the exception of the Cargo-type Master.

1979 Master Model and Ford Escort third series models.

1979 Master Model and Ford Escort third series models. 1980 Master Model and Ford Sierra models.

1980 Master Model and Ford Sierra models.

1980 Master Model and Ford Fiesta second series models.

1980 Master Model and Ford Fiesta second series models. 1981 Master Model and Ford Orion models

1981 Master Model and Ford Orion models

1982 Master Model and Ford Scorpio models.

1982 Master Model and Ford Scorpio models. 1982 Master Model and Ford Transit fourth series models.

1982 Master Model and Ford Transit fourth series models.

1990 Master Model and Ford Mondeo models first series.

1990 Master Model and Ford Mondeo models first series.

The work, although by Ford Cologne, was handled in England by Sid Kallar, project manager of the Ford Europe model shop.

The English manager traveled non-stop from London to Turin every two weeks from 1978 until 1990, when he retired.

It was from him and the company he represented, that the technicians and managers of Alfredo Stola & sons learned so much about Anglo-Saxon management and working methods.

Novembre 1990 Sid Kallar (al centro con la cravatta) festeggia insieme ai tecnici e alle segretarie della Alfredo Stola & Figli il suo ultimo giorno di lavoro in Ford. Da sinistra Sellan Sante, Alfredo Stola, Massimo Stola, Sid Kallar, Alberto Sasso, Bolle, Hans Widdish,

Novembre 1990 Sid Kallar (al centro con la cravatta) festeggia insieme ai tecnici e alle segretarie della Alfredo Stola & Figli il suo ultimo giorno di lavoro in Ford. Da sinistra Sellan Sante, Alfredo Stola, Massimo Stola, Sid Kallar, Alberto Sasso, Bolle, Hans Widdish, Da sinistra Grazia Bolla, Enza, Sid Kallar, Carla, Sardi Giovanna e Laura Giunipero.

Da sinistra Grazia Bolla, Enza, Sid Kallar, Carla, Sardi Giovanna e Laura Giunipero. 1990 In the historical room of Via La Thuile 71 Sid Kallar in the center with the two union representatives of the company, on the left Danzi and on the right Cellura.

1990 In the historical room of Via La Thuile 71 Sid Kallar in the center with the two union representatives of the company, on the left Danzi and on the right Cellura. 1990 Sid Kallar and Alfredo Stola.

1990 Sid Kallar and Alfredo Stola.

1980 Master Model Fiat Uno 5 door

1980 Master Model Fiat Uno 5 door 1980 Master Model Fiat Uno 5 door

1980 Master Model Fiat Uno 5 door

1980 Master Model Fiat Uno 3 door

1980 Master Model Fiat Uno 3 door 1980 Master Model Fiat Uno 3 door

1980 Master Model Fiat Uno 3 door

1980 Fiat Uno special Master for use in the Fiat design office for visible welding point verification through the transparent outer skin made of plexiglass.

1980 Fiat Uno special Master for use in the Fiat design office for visible welding point verification through the transparent outer skin made of plexiglass. 1980 Fiat Uno special Master for use in the Fiat design office for visible welding point verification through the transparent outer skin made of plexiglass.

1980 Fiat Uno special Master for use in the Fiat design office for visible welding point verification through the transparent outer skin made of plexiglass.

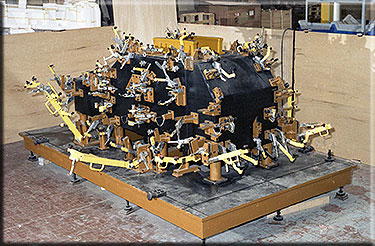

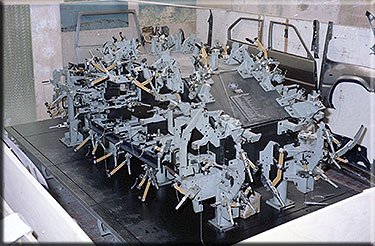

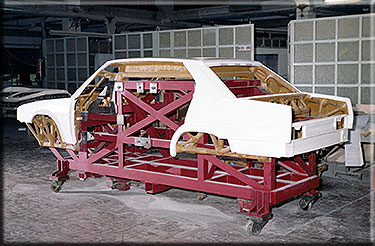

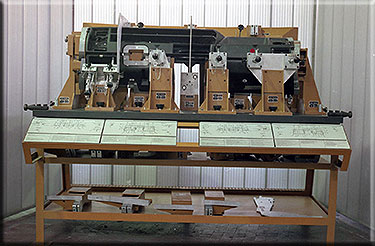

1981 Fiat Uno control jig for exterior and interior panels,

1981 Fiat Uno control jig for exterior and interior panels,

3 door versions. 1981 Fiat Uno control jig for exterior and interior panels,

1981 Fiat Uno control jig for exterior and interior panels,

5 door versions.

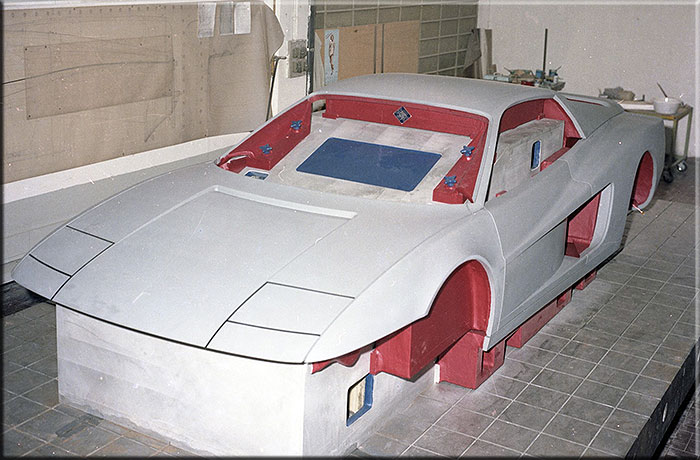

1980 Master Model Lancia 037 built for Pininfarina.

1980 Master Model Lancia 037 built for Pininfarina. 1980 Master Model Lancia 037 built for Pininfarina.

1980 Master Model Lancia 037 built for Pininfarina.

1980 Lancia 037 Master Model front view.

1980 Lancia 037 Master Model front view.

1980 Alfa Romeo - Arna Master of control of all sheet metal of the four-door version.

1980 Alfa Romeo - Arna Master of control of all sheet metal of the four-door version. For the Stola the first “reverse engineering” work with the starting point is the Nissan Pulsar / Cherry.

For the Stola the first “reverse engineering” work with the starting point is the Nissan Pulsar / Cherry.

1981 Piaggio control jig of the Vespa PK.

1981 Piaggio control jig of the Vespa PK. 1981 Piaggio control jig of the Vespa PK.

1981 Piaggio control jig of the Vespa PK.

1981 Fiat Master Model Regata.

1981 Fiat Master Model Regata. 1981 Alfa Romeo Master Model Type 33 Sport Wagon derived from the Master Model 33 sedan.

1981 Alfa Romeo Master Model Type 33 Sport Wagon derived from the Master Model 33 sedan.

1981 for Pinifarina Master Model of Ferrari Testarossa.

1981 for Pinifarina Master Model of Ferrari Testarossa.

1981 for Pinifarina Master Model of Ferrari Testarossa.

1981 for Pinifarina Master Model of Ferrari Testarossa.

1982 Alfa Romeo Master Model type 90.

1982 Alfa Romeo Master Model type 90.

1982 Alfa Romeo Master Model type 90 for sheet metal control.

1982 Alfa Romeo Master Model type 90 for sheet metal control. 1982 Alfa Romeo Master Model type 90 for control.

1982 Alfa Romeo Master Model type 90 for control.

1982 Alfa Romeo Master Model type Alfa 90.

1982 Alfa Romeo Master Model type Alfa 90. 1982 Alfa Romeo Master Model type Alfa 90.

1982 Alfa Romeo Master Model type Alfa 90.

1982 Master Model of a Ford Falcon for Ford Australia that never went into production.

1982 Master Model of a Ford Falcon for Ford Australia that never went into production. 1982 Master Model of a Ford Falcon for Ford Australia that never went into production.

1982 Master Model of a Ford Falcon for Ford Australia that never went into production.

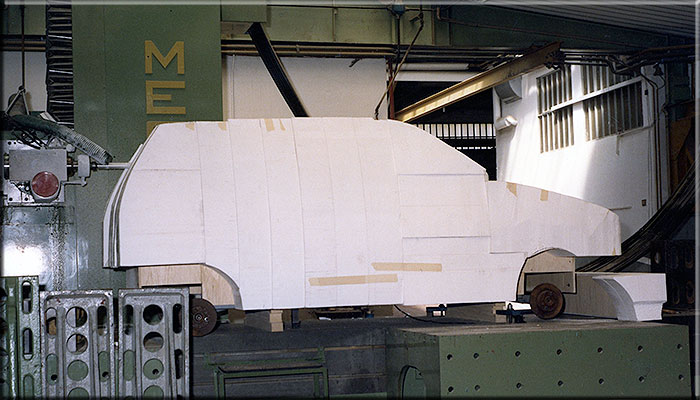

1982 The complete Masters are mostly still handmade. At the experimental level, we try to mill

1982 The complete Masters are mostly still handmade. At the experimental level, we try to mill

the Master Model of the Fiat Uno that in 1980 had been made by hand.

1983 Alfa Romeo Master Model type 75 for sheet metal control.

1983 Alfa Romeo Master Model type 75 for sheet metal control.

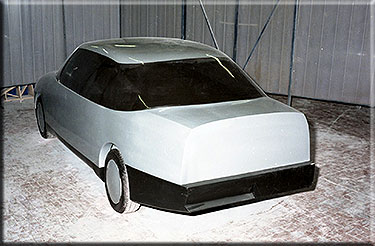

In 1983 Alfredo Stola & Sons received an unusual order from Fiat’s the wind tunnel department.

Fiat's engineer Nevio Di Giusto based in Orbassano, had to create a model with an aerodynamic floor designed by Professor Alberto Morelli, professor of aerodynamics at the Polytechnic of Turin.

This was no longer an experiment but a real job, paid for by a customer and in particular was the first model in 1: 1 scale made by Numerical Control from Stola.

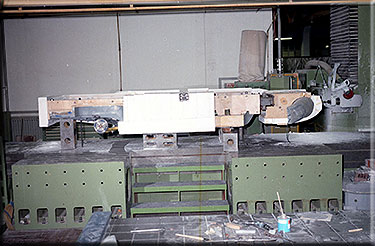

1983 Construction of the adjustable aerodynamic frame.

1983 Construction of the adjustable aerodynamic frame. 1983 milling of the polystyrene model.

1983 milling of the polystyrene model.

1983 The aerodynamic model designed by Professor Alberto Morelli painted and ready to be tested at the Fiat Wind Tunnel Center in Orbassano.

1983 The aerodynamic model designed by Professor Alberto Morelli painted and ready to be tested at the Fiat Wind Tunnel Center in Orbassano. 1983 The aerodynamic model designed by Professor Alberto Morelli painted and ready to be tested at the Fiat Wind Tunnel Center in Orbassano.

1983 The aerodynamic model designed by Professor Alberto Morelli painted and ready to be tested at the Fiat Wind Tunnel Center in Orbassano.

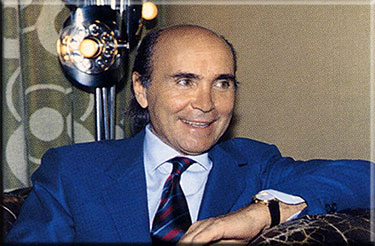

1983 Roberto Stola in his office on the first floor

1983 Roberto Stola in his office on the first floor

of Via La Thuile 71.In the 1980's Fiat, Lancia and Alfa Romeo continued to be very important customers.

The collaboration with Ford was seen by them as positive confirmation of the qualities of the company who had been a supplier to them for 60 years.

Without revealing secrets, it is in the nature of these relationships that new ideas and experiences could be shared with the American manufacturer and its bases in Germany and England.

Not just in methods, but also materials, support structures built in a Swiss/German aluminium honeycomb material and aluminum represented a big step forward.

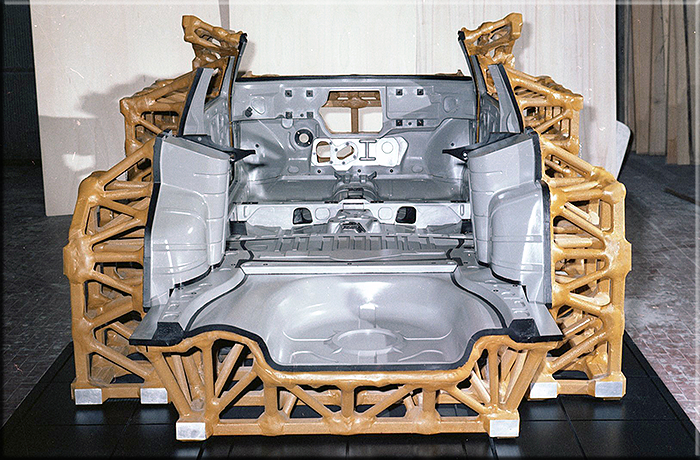

After the first 4 years of collaboration, Ford asked the Stolas to research and develop the idea of cubing control models. 1993 Josef Munsch, director of model departments Ford Europe until 1993, the year in which he retired.In 1982, after disappointing quality results of the Ford Sierra in the pre-production assembly phase a paper project was carried out by the technical office of Alfredo Stola & sons and approved by the Ford managers.

1993 Josef Munsch, director of model departments Ford Europe until 1993, the year in which he retired.In 1982, after disappointing quality results of the Ford Sierra in the pre-production assembly phase a paper project was carried out by the technical office of Alfredo Stola & sons and approved by the Ford managers.

The construction of this Cubing model was carried out in Cologne and it is highly likely that it was the first complete testing tool made in the world for interiors and exteriors to be used on the assembly line. 1982 The Cav. Luciano Guasco of Fiat and Roberto Stola.On the occasion of the Ritmo restyling project,in 1982 the Stola model shop delivered to Fiat a Cubing model called an "Assembly Master".

1982 The Cav. Luciano Guasco of Fiat and Roberto Stola.On the occasion of the Ritmo restyling project,in 1982 the Stola model shop delivered to Fiat a Cubing model called an "Assembly Master".

Presented at the Fiat technology department directed by Cav. Luciano Guasco and his assistant Giuseppe Luisolo it was accepted in partial form as a check for the front alone. This was also given for free, a gamble which paid off as from that time Fiat always requested an Assembly Master for each model of car at each production site.

The construction technology and manual details were reproduced in resin.

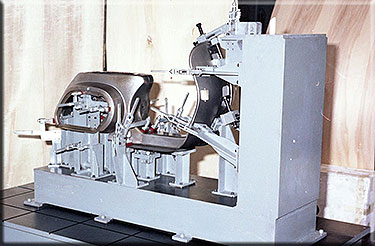

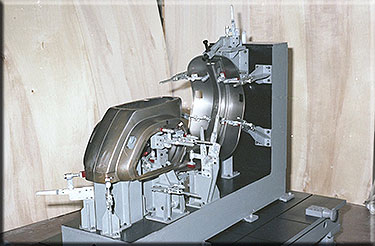

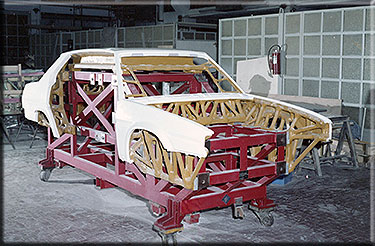

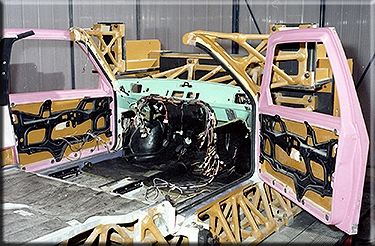

1982 Fiat Uno Interior Fitting Master.

1982 Fiat Uno Interior Fitting Master. 1982 Fiat Uno Interior Fitting Master.

1982 Fiat Uno Interior Fitting Master.

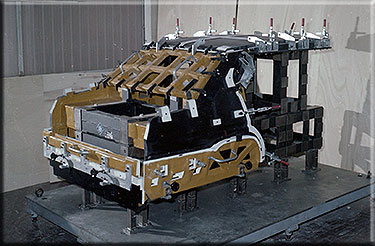

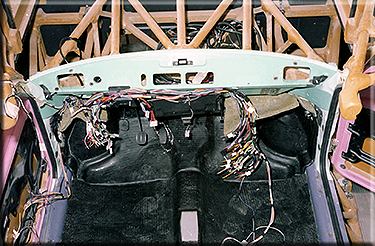

1988 Master Interior Fitting Fiat Tipo.

1988 Master Interior Fitting Fiat Tipo. 1988 Master Interior Fitting Fiat Tipo.

1988 Master Interior Fitting Fiat Tipo.

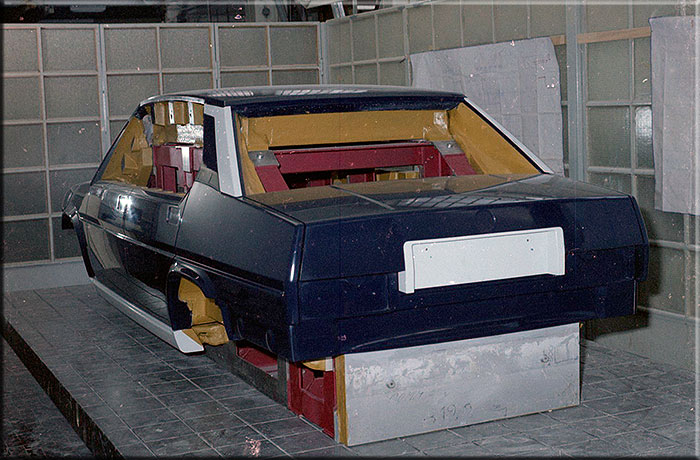

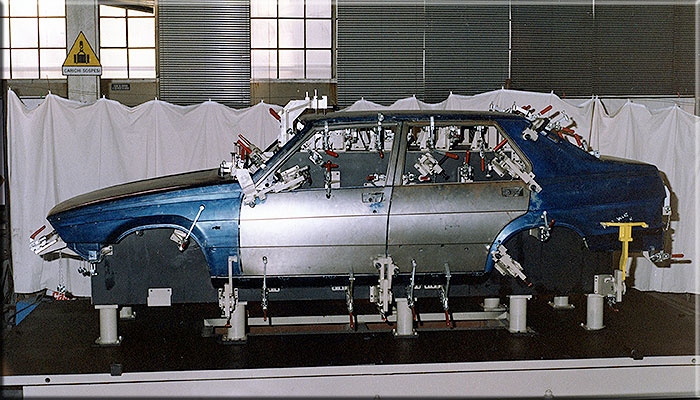

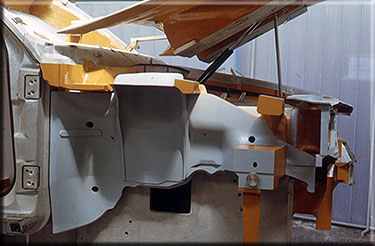

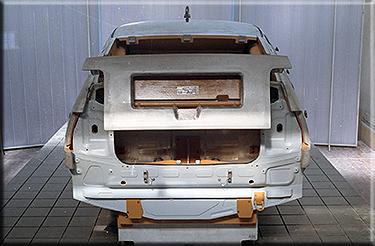

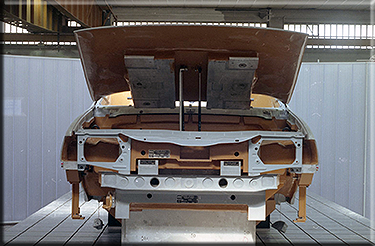

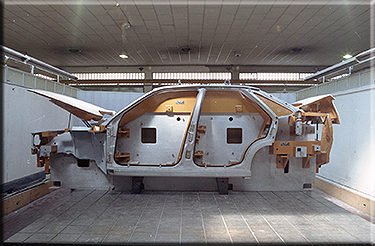

1988 Exterior Fitting Master Fiat Tipo.

1988 Exterior Fitting Master Fiat Tipo. 1988 Exterior Fitting Master Fiat Tipo.

1988 Exterior Fitting Master Fiat Tipo.

1988 Partial Assembly Masterfor the Fiat Tipo instrument panel.

1988 Partial Assembly Masterfor the Fiat Tipo instrument panel. 1988 Partial Assembly Masterfor the Fiat Tipo instrument panel.

1988 Partial Assembly Masterfor the Fiat Tipo instrument panel.

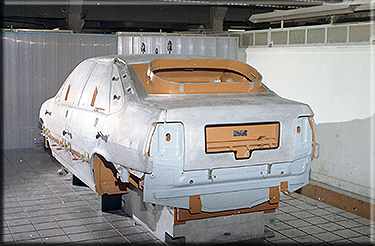

1990 Fiat Tempra Exterior Fitting Master.

1990 Fiat Tempra Exterior Fitting Master. 1990 Fiat Tempra Exterior Fitting Master.

1990 Fiat Tempra Exterior Fitting Master.

1990 Fiat Tempra Exterior Fitting Master.

1990 Fiat Tempra Exterior Fitting Master. 1990 Fiat Tempra Exterior Fitting Master.

1990 Fiat Tempra Exterior Fitting Master.

1993 Lancia Kappa assembly master model.

1993 Lancia Kappa assembly master model.

From the second half of the 1990's,These "Assembly Masters" were promoted in Europe and Asia by the major auto manufacturers, from this initiative VW group became a major customer.

The resin was replaced by forged aeronautical aluminum with some details being made in carbon fiber.